Delve into the captivating world of wafer fab and advanced display parks.

From basics to cutting-edge advancements, this journey unveils the heart of technological progress.

Semiconductor technology, rooted in materials like silicon, gives life to the devices we can’t imagine living without—smartphones, computers, and more.

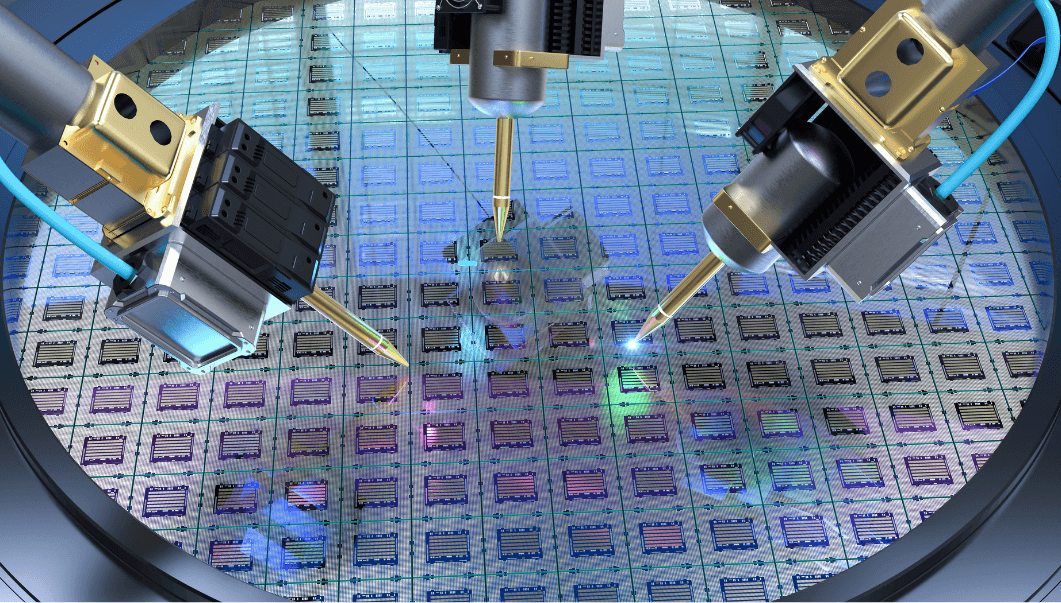

The nucleus of this industry lies in wafer fabrication, an art where meticulously crafted wafers undergo a metamorphosis into intricate circuit designs.

Key Takeaways

- Semiconductor Tech in Electronics: Semiconductor technology, centered on silicon, underpins modern electronics, creating transistors, diodes, and integrated circuits powering devices like phones, computers, and TVs.

- Wafer Fab in Singapore: Singapore’s strategic location and infrastructure make it a global semiconductor hub. Wafer fabrication, crucial in semiconductor production, involves deposition, etching, and lithography to craft intricate circuit designs.

- Key Players in Singapore: Leading companies like Infineon Technologies and Toshiba contribute to Singapore’s semiconductor growth, fostering a dynamic ecosystem.

- Evolution of Fabrication: Semiconductor fabrication has evolved from silicon wafers to advanced display parks producing flat panel displays, LCDs, and mobile screens. MEMS and GaN technologies also play roles.

- Display Industry Trends: OLED and MicroLED displays are emerging with brighter and energy-efficient visuals. Advanced fabrication techniques are essential to accommodate these evolving trends.

- Advancements in Wafer Fabrication: Technological advancements enable smaller, more powerful electronic components. New wafer fabrication plants in Singapore, with state-of-the-art equipment, meet the demand for advanced devices.

- Tampines Wafer Fab Park: A thriving hub in Singapore’s semiconductor ecosystem, Tampines Wafer Fab Park fosters research, development, and collaboration, driving innovation.

- Collaboration for Innovation: Strong collaboration between JTC and industry leaders fuels Tampines Wafer Fab Park’s success, promoting a conducive environment for semiconductor manufacturing.

- Singapore’s Semiconductor Hubs: Beyond Tampines, Singapore boasts other semiconductor hubs, fostering a vibrant ecosystem attracting local and international companies.

- JTC and Industry Partnerships: JTC partners with industry leaders for semiconductor innovation, offering infrastructure, grants, and incentives to promote research, development, and growth.

Understanding Semiconductor Manufacturing: Exploring the Role of Wafers and Fabrication

The Basics of Semiconductor Technology

Semiconductor technology is the backbone of modern electronics.

It involves using materials, primarily silicon, to create electronic devices such as transistors, diodes, and integrated circuits.

These devices are essential in smartphones, computers, televisions, and other electronic gadgets.

The Importance of Wafer Fab in Singapore

Singapore has positioned itself as a global hub for semiconductor manufacturing due to its strategic location, robust infrastructure, and supportive government policies.

One crucial aspect of semiconductor manufacturing is wafer fabrication.

Wafer fab refers to creating semiconductor wafers, the foundation for manufacturing electronic components.

These wafers undergo several fabrication steps, including deposition, etching, and lithography, to create intricate circuit designs.

Key Players in Semiconductor Fabrication

Singapore is home to several key players in the semiconductor fabrication industry.

Infineon Technologies, Toshiba, and various other multinational companies have established their presence in the country.

These industry leaders contribute to the growth and development of the semiconductor ecosystem in Singapore.

The Evolution of Wafer Fabrication: From Silicon to Advanced Display Parks

The Journey from Silicon to Advanced Display Parks

Over the years, wafer fabrication has evolved significantly.

The industry has expanded into advanced display parks since the initial focus on silicon wafers.

These parks specialize in producing flat panel displays, LCDs, and mobile phone screens.

Advanced technologies such as MEMS (Micro-Electro-Mechanical Systems) and GaN (Gallium Nitride) have also found their applications in wafer fabrication.

Emerging Trends in the Display Industry

The display industry is witnessing significant advancements, driven by the increasing demand for high-resolution screens and innovative display technologies.

OLED (Organic Light Emitting Diode) and MicroLED displays are becoming more prevalent, offering brighter and more energy-efficient visuals.

These emerging trends require advanced fabrication techniques and specialized manufacturing facilities.

Upcoming Developments in Wafer Fabrication

The wafer fabrication industry is constantly evolving.

With technological advancements, smaller and more powerful electronic components can be produced.

2021 has seen the emergence of new wafer fabrication plants in Singapore, enhancing the country’s capabilities in semiconductor manufacturing.

These facilities have state-of-the-art equipment and employ innovative techniques to meet the growing demand for advanced electronic devices.

Singapore’s Thriving Semiconductor Ecosystem: Tampines Wafer Fab Park and Beyond

Tampines Wafer Fab Park: A Hub of Innovation

Located in eastern Singapore, Tampines Wafer Fab Park is a prime example of Singapore’s thriving semiconductor ecosystem.

The park serves as a hub for research, development, and manufacturing activities related to wafer fabrication.

It houses multiple fabrication plants, research institutes, and test facilities, fostering collaboration and innovation.

Collaboration between JTC and Semiconductor Industry Leaders

The success of Tampines Wafer Fab Park can be attributed to the strong collaboration between JTC (Jurong Town Corporation) and semiconductor industry leaders.

JTC, a government agency responsible for Singapore’s industrial infrastructure, works closely with companies to provide a conducive environment for semiconductor manufacturing.

This collaboration ensures that the park remains at the forefront of technological advancements.

Beyond Tampines: Other Semiconductor Hubs in Singapore

In addition to Tampines Wafer Fab Park, Singapore boasts other semiconductor hubs such as the Tainan Science Park, Hsinchu Science Park, and the Central Taiwan Science Park.

These hubs attract local and international companies, creating a vibrant ecosystem that drives the growth of the semiconductor industry in the region.

Building the Future: Collaboration Between JTC and Semiconductor Industry Leaders

Partnerships and Initiatives Driving Semiconductor Innovation

Collaboration is critical to driving semiconductor innovation in Singapore.

Through partnerships and initiatives, JTC and semiconductor industry leaders promote knowledge-sharing, research, and development activities.

These collaborations foster a culture of innovation, ensuring Singapore remains a global leader in semiconductor manufacturing.

JTC’s Role in Supporting the Semiconductor Industry

JTC plays a vital role in supporting the semiconductor industry in Singapore.

It provides companies with the necessary infrastructure to facilitate efficient and high-quality semiconductor production, including advanced manufacturing facilities and cleanroom spaces.

JTC also offers grants and incentives to encourage research and development, attracting foreign investments and nurturing local startups.

The Vision for Future Growth and Development

Singapore’s vision for the future of semiconductor manufacturing is focused on advanced manufacturing, innovation, and sustainability.

The country aims to strengthen its position as a global semiconductor hub, attracting more investments and fostering the growth of local talent.

By continually embracing new technologies and driving research and development, Singapore is poised to shape the semiconductor industry’s future.

Cutting-Edge Technology: Wafer Fabrication Plants and the Electronics Industry

The Role of Wafer Fabrication Plants in the Electronics Industry

Wafer fabrication plants are an integral part of the electronics industry.

These facilities produce the semiconductor wafers that form the building blocks of electronic devices.

From smartphones to computers, wafer fabrication plants enable the manufacturing of advanced and energy-efficient electronics that power our daily lives.

Advancements in Wafer Fabrication Technology

The field of wafer fabrication is constantly advancing.

New techniques and materials are being developed to enhance the performance and efficiency of electronic devices.

From advanced lithography methods to innovative deposition and etching processes, wafer fabrication technology is critical in pushing the boundaries of what is achievable in the electronics industry.

Exploring New Frontiers: Mobile Phone Displays and Beyond

One area where wafer fabrication is making significant contributions is mobile phone displays.

As smartphone screens become more prominent, thinner, and more vibrant, wafer fabrication plants are at the forefront of meeting the demands of the mobile phone industry.

Newer technologies, such as flexible displays and foldable screens, are also being developed, opening up new possibilities for the future of smartphones and other electronic gadgets.

A Look Inside Tampines Wafer Fab Park: Advancements, Facilities, and Sustainability

Introduction to Tampines Wafer Fab Park

Tampines Wafer Fab Park, located in eastern Singapore, is a state-of-the-art facility that houses semiconductor fabrication plants.

It is a strategic hub for companies in the semiconductor industry, providing a conducive environment for research, development, and production of advanced semiconductor technologies.

Sustainable Practices in Tampines Wafer Fab Park

Tampines Wafer Fab Park strongly emphasizes sustainability and environmentally friendly practices.

The facility has advanced technologies for energy efficiency, waste reduction, and water conservation.

By implementing stringent measures and adhering to global standards, the park aims to minimize its carbon footprint and contribute to a greener future.

Futuristic Facilities and Technologies in Tampines Wafer Fab Park

With the rapid advancements in semiconductor technology, Tampines Wafer Fab Park boasts state-of-the-art facilities and technologies.

One of the notable advancements is ion implantation technology, which is utilized in the fabrication process to enhance the performance of semiconductor devices.

Companies like Taiwan Semiconductor Manufacturing Company (TSMC) and Advanced Micro Devices (AMD) have established a presence in Tampines Wafer Fab Park, leveraging these advanced technologies to drive innovation and meet the market’s growing demands.

Singapore’s Semiconductor Industry Growth: 2021 to 2023 and Beyond

An Overview of Singapore’s Semiconductor Industry

Singapore’s semiconductor industry has been a critical economic growth and innovation driver.

The industry encompasses various sectors, including analog/mixed-signal semiconductor foundry, power semiconductors, and display technologies.

Singapore has positioned itself as a global hub for semiconductor manufacturing, attracting top tech companies and fostering a collaborative ecosystem for research and development.

Growth Opportunities and Projections for 2021 to 2023

The semiconductor industry in Singapore is expected to continue its growth trajectory from 2021 to 2023.

With the increasing demand for advanced semiconductor devices in various sectors such as artificial intelligence, Internet of Things, and autonomous vehicles, Singapore is well-positioned to capitalize on these opportunities.

The Singapore Economic Development Board (EDB) has projected a positive outlook for the industry, with investments and collaborations set to drive innovation and propel growth.

Factors Driving the Future Growth of the Semiconductor Industry in Singapore

Several factors contribute to the future growth of Singapore’s semiconductor industry.

Strategic partnerships and initiatives play a crucial role in advancing semiconductor manufacturing.

The EDB’s efforts in promoting semiconductor manufacturing, collaborative partnerships with industry players, and government initiatives and incentive programs have created a favorable environment for industry players to thrive.

Additionally, world-class research institutions and higher learning institutes further strengthen Singapore’s position as a global hub for semiconductor innovation and production.

Strategic Partnerships and Initiatives: EDB’s Role in Advancing Semiconductor Manufacturing

EDB’s Efforts in Promoting Semiconductor Manufacturing

The Singapore Economic Development Board (EDB) plays a pivotal role in promoting semiconductor manufacturing in Singapore.

EDB works closely with industry players, providing support and incentives to encourage investments, research and development, and the establishment of semiconductor manufacturing facilities.

Through its initiatives, EDB aims to enhance the competitiveness of Singapore’s semiconductor industry and attract global players to set up operations in the country.

Collaborative Partnerships with Industry Players

Collaborative partnerships between the EDB and industry players have driven innovation and technological advancements in semiconductor manufacturing.

These partnerships enable knowledge sharing, joint research and development projects, and the exchange of best practices.

By fostering collaboration, Singapore’s semiconductor industry can stay at the forefront of technological advancements and meet the evolving needs of the global market.

Government Initiatives and Incentive Programs for the Semiconductor Industry

The Singapore government has introduced various initiatives and incentive programs to support the semiconductor industry.

These programs aim to attract investment, promote research and development, and facilitate skills development in the semiconductor sector.

Some of the initiatives include the India Semiconductor Mission, which encourages collaboration between Indian and Singaporean companies, and grants and tax incentives provided by the government to promote technological innovation and growth.

From Silicon to Circuit: Exploring the Process of Semiconductor Fabrication

Introduction to Semiconductor Fabrication Process

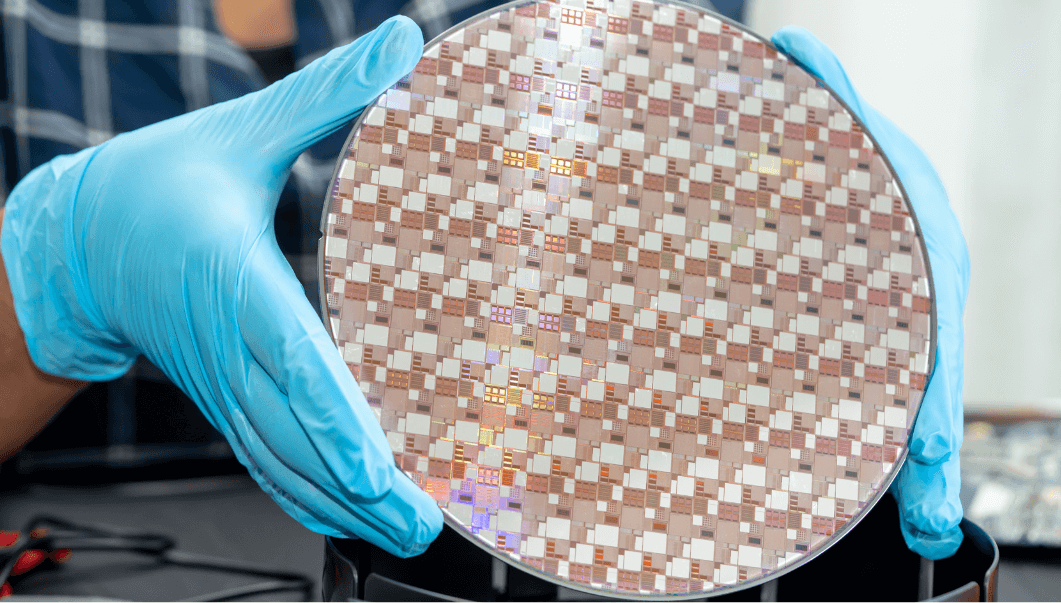

Semiconductor fabrication is a complex process that involves multiple steps to transform silicon wafers into functional integrated circuits.

The method includes various stages: wafer manufacturing, deposition, lithography, etching, and packaging.

Each step requires precise control and adherence to stringent quality standards to ensure the production of high-performance semiconductor devices.

Key Steps in Semiconductor Fabrication

Semiconductor fabrication involves several key steps that are essential to the manufacturing process.

These include cleaning and etching the wafer surface, depositing thin layers of materials through techniques like chemical vapor deposition, and defining patterns using photolithography.

Different process steps are repeated to create complex integrated circuits with multiple layers and functionalities.

Advancements in Semiconductor Fabrication Technologies

The semiconductor industry is constantly evolving, and advancements in fabrication technologies play a significant role in driving innovation.

Technologies such as extreme ultraviolet lithography (EUV) and ion implantation have revolutionized manufacturing, enabling the production of smaller, faster, and more efficient semiconductor devices.

Continuous research and development efforts aim to enhance the fabrication process, developing state-of-the-art gadgets and technologies.

Innovations in Display Technology: Impact of Semiconductor Manufacturing on Advanced Displays

The Role of Semiconductor Manufacturing in Advanced Display Technology

Semiconductor manufacturing plays a crucial role in advancing display technologies.

Semiconductor devices are integrated into display panels, enabling various functionalities and enhancing performance.

From LCD to OLED and MicroLED displays, semiconductor manufacturing provides the backbone for these advanced technologies, enabling high-resolution visuals, improved color accuracy, and energy efficiency.

Advancements in Display Technology Enabled by Semiconductor Manufacturing

Semiconductor manufacturing has enabled significant advancements in display technology.

Miniaturization of transistors and improved pixel densities have led to sharper and more vibrant displays.

Additionally, innovations in semiconductor materials and manufacturing processes have facilitated the development of flexible and curved displays, providing new possibilities for design and user experience.

Trends and Future Developments in Advanced Display Manufacturing

The future of advanced display manufacturing holds exciting possibilities.

With the increasing demand for immersive visual experiences, technologies like augmented reality (AR) and virtual reality (VR) are expected to drive growth in the display industry.

Display manufacturers are exploring new materials like quantum dots and organic semiconductors to create displays with better color gamut and energy efficiency.

The convergence of display technologies with other emerging fields like photonics and AI opens up a world of new applications and opportunities.

Nurturing Innovation: Singapore’s Clusters and Parks as Hubs for Semiconductor R&D

Singapore’s Semiconductor Industry Growth

The semiconductor industry in Singapore has been increasing in recent years.

With specialized parks and advanced facilities, the industry has witnessed significant advancements in technology and research.

The Role of Clusters and Parks in Driving Innovation

Singapore’s clusters and parks provide a collaborative environment for industry players, researchers, and academics to come together and drive innovation in the semiconductor industry.

These clusters act as hubs for research and development, fostering the growth of new ideas and technologies.

Semiconductor Equipment and Materials International (SEMI) Standards

SEMI standards are crucial in maintaining the quality and reliability of semiconductor equipment and materials.

Singapore follows these standards to ensure that the semiconductor industry operates at the highest level of efficiency and consistency.

Building a Sustainable Future: Clean Rooms and Stringent Standards in Wafer Fabrication

The Importance of Clean Rooms in Wafer Fabrication

Clean rooms are essential in wafer fabrication as they provide a contamination-free environment for producing high-quality semiconductor wafers.

These controlled environments ensure that the wafers meet the required cleanliness standards.

Stringent Standards for Quality Assurance

To ensure the highest quality level, Singapore’s semiconductor industry follows stringent standards for quality assurance.

These standards cover various aspects of the fabrication process, from manufacturing to testing and packaging.

Advancements in Wafer Fab Equipment

The advancements in wafer fab equipment have significantly improved the efficiency and productivity of the fabrication process.

The use of cutting-edge technology and automation has reduced production time and increased yield, contributing to the overall growth of the semiconductor industry.

Advancing the Next Generation: Role of AI and Institutes of Higher Learning in Semiconductor Industry

AI Integration in Semiconductor Manufacturing

Artificial intelligence (AI) revolutionizes the semiconductor industry by enabling advanced process control, yield optimization, and defect detection.

Singapore has embraced AI integration in semiconductor manufacturing, improving efficiency and productivity.

Partnerships with Institutes of Higher Learning

Singapore actively collaborates with institutes of higher learning to drive research and development in the semiconductor industry.

These partnerships facilitate knowledge exchange, talent development, and the creation of a skilled workforce.

Creation of a Skilled Workforce for the Semiconductor Industry

Singapore recognizes the importance of a skilled workforce in driving the semiconductor industry forward.

Efforts are being made to provide specialized training and education, ensuring Singaporeans have the necessary skills to contribute to the industry’s growth.

Global Leadership in Semiconductors: Insights from Industry Leaders like Intel’s Pat Gelsinger

Intel’s Role in the Semiconductor Industry

Intel is a leading player in the semiconductor industry, constantly pushing the boundaries of technology and innovation.

The company’s contributions and strategies provide valuable insights into the global semiconductor landscape.

Future Trends and Technologies in Semiconductors

The semiconductor industry constantly evolves, with new trends and technologies emerging regularly.

Staying updated with these advancements is crucial for Singapore to maintain its global leadership position.

Lessons from Pat Gelsinger’s Leadership

Pat Gelsinger’s leadership at Intel offers valuable lessons for Singapore’s semiconductor industry.

His vision, strategic thinking, and ability to drive innovation can serve as a guide for Singapore’s ambitions in this sector.

Singapore’s Ambitions: Becoming a Global Node for Semiconductors and Integrated Circuits

Tampines Advanced Display Park: The Future of Display Technology

Singapore’s Tampines Advanced Display Park is at the forefront of display technology.

The park focuses on research and development of deformable displays, offering new possibilities for innovative products and user experiences.

Deformable Displays and the Next Wave of Innovation

Deformable displays hold immense potential for the next wave of innovation in the semiconductor industry.

They enable the creation of flexible, foldable, and rollable electronic devices, revolutionizing how we interact with technology.

Expandable and Free-form Displays: Transforming User Experience

Expandable and free-form displays are another area of research in Singapore’s display technology sector.

These displays offer a transformative user experience, allowing for more immersive and interactive applications.

Conclusion

Get ready to embark on a captivating journey into the world of cutting-edge technology and innovation.

The realm of semiconductor manufacturing is where the magic happens, fueling the devices that power our modern lives.

From smartphones to smart TVs, semiconductor technology weaves its intricate web, enabling us to connect, communicate, and create.

Imagine a place where wafer fabrication isn’t just a process but a symphony of precision and creativity.

Welcome to Singapore, a global hub that has carved its niche in the semiconductor landscape.

The importance of wafer fabrication is hard to overstate – it’s where the foundation for electronic marvels is laid.

Layers of deposition, etching, and lithography combine to create circuits that defy imagination.

Frequently Asked Questions

What is a wafer fab?

A wafer fab, short for wafer fabrication facility, is a manufacturing facility that specializes in producing integrated circuits on silicon wafers.

What are advanced display parks?

Advanced display parks are specialized facilities that focus on developing and producing advanced display technologies, such as 3D dynamic displays and deformable displays.

Are there any wafer fab and advanced display parks in Singapore?

Singapore has several wafer fabs and advanced display parks, such as the Tampines and Pasir Ris facilities.

Which companies operate wafer fabs and advanced display parks in Singapore?

Companies like Abu Dhabi Electronics, Advanced Micro Devices (AMD), Aizu Fujitsu Semiconductor, Crocus Nano Electronics Advancements, Infineon, Samsung Electronics, and Hua Hong Semiconductor are some of the companies operating in these specialized parks.

What are the trends in the display industry?

The display industry is witnessing technological advancements like 3D dynamic displays, deformable displays, and next-generation display technologies.

There is also a focus on the production of advanced microdevices.

When was the wafer fab and advanced display park sector launched in Singapore?

Singapore’s wafer fab and advanced display park sector was launched in 2022.

What is the expected investment in the wafer fab and advanced display park sector in Singapore?

The Singapore government aims to invest around $10 billion to rejuvenate the wafer fab and advanced display park sector and establish it as a leading-edge manufacturing hub.

Who announced the investment plan for the wafer fab and advanced display park sector in Singapore?

The Minister for Trade and Industry announced the investment plan for the wafer fab and advanced display park sector in Singapore.

When is the completion date for the wafer fab and advanced display park sector rejuvenation plan in Singapore?

The completion date for Singapore’s wafer fab and advanced display park sector rejuvenation plan is 2024.

What is the role of Intel CEO Pat Gelsinger in the wafer fab and advanced display park sector?

Intel CEO Pat Gelsinger is leading the company’s efforts to build a new manufacturing facility and graduate from being only an IC design company to a leading-edge wafer fab and advanced display park operator globally.